-

Call-center

+998 78 141 90 99 -

Helpline

+998 71 619 23 33

The Almalyk Mining and Metallurgical Complex is developing “Smart mines”

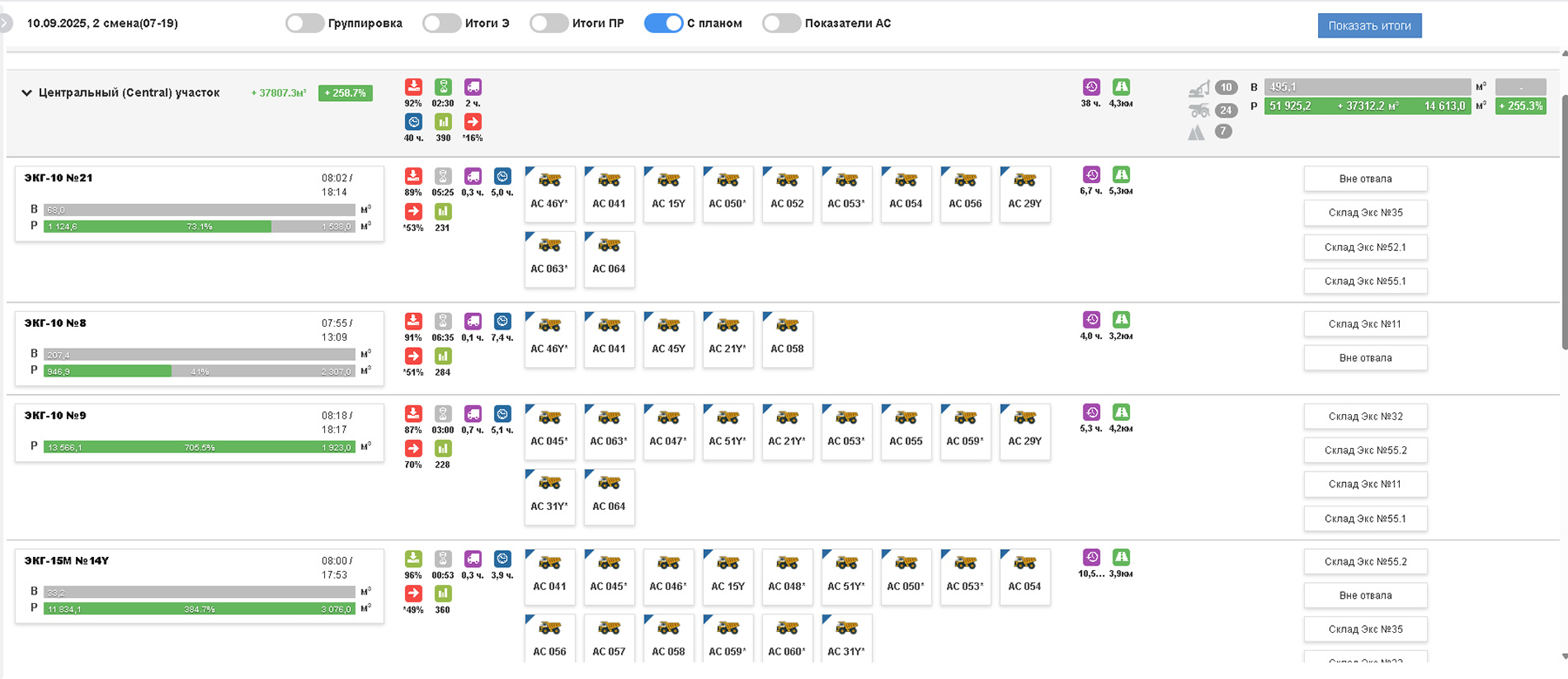

As is well known, extensive digitalization initiatives across enterprises of the Almalyk Mining and Metallurgical Complex are leading to higher labor productivity. Currently, as part of this digital transformation, the Complex is nearing completion of the implementation of a comprehensive automated mine and transportation management system.

This is the first project of its kind in Uzbekistan’s mining industry, and its core objective is to fundamentally transform mine operations through advanced digital technologies.

Implemented under the “Digital Uzbekistan – 2030” National Strategy, the project focuses on improving efficiency, reducing operating costs, and ensuring maximum safety at the Complex’s two major mining sites — “Kalmakyr” and “Yoshlik I”.

Within the project, more than 400 mining vehicles and machines have been equipped with various sensors. Specifically:

- 186 units at the “Kalmakyr” mine, and

- 240 units at the “Yoshlik I” mine — including excavators, haul trucks, drilling rigs, and other heavy equipment — are now able to automatically transmit operational data to the “Karier” Automated Mine Transport Management Information System.

“This system allows for 24/7 monitoring of mining operations, real-time control of haul truck movements, accurate tracking of transported ore volumes, and automated monitoring of speed limits and permissible load levels, which significantly reduces fuel consumption and operating costs,” said Aziz Roziqulov, Director of the Digitalization Department at the Almalyk Mining and Metallurgical Complex.

The functional capability of the “Karier” automated system is based on data collection from sensors installed on haul trucks, excavators, drilling machines, and other mobile units. These sensors record:

- Level of material in haul truck bodies

- Fuel levels

- Current location

- Load weight

- Wear levels of drilling tools and components

All data is wirelessly transmitted to a central server, where analytical software processes the information, enabling reporting and decision-making.

The “Smart Quarry” (Intelligent Mining System) also optimizes transportation logistics. Haul trucks and rail transport units are equipped with on-board systems for automatic route planning.

Additionally, a real-time ore accounting system has been implemented. This solution ensures:

- Automatic tracking of equipment downtime and its causes

- Automated weight measurement of ore transported in haul trucks

- Monitoring of tire pressure and fuel consumption

To improve operational safety in mining conditions, a driver fatigue monitoring system has also been introduced. This system detects loss of attention or signs of drowsiness in drivers and operators, issuing instant alerts.

The system also enables quality control of ore being shipped and generates required analytical reports. Equipping drilling rigs with sensors allows precise monitoring of actual drilled holes, their technological parameters, tool wear, and downtime.

According to research, the use of an intelligent mining system can:

- Increase the productivity of haul trucks and excavators by an average of 10%

- Increase average fleet speed by 5%

- Improve equipment utilization rates by up to 20%

This project not only strengthens the leadership position of the Almalyk Mining and Metallurgical Complex as the largest copper producer in the region, but also sets a new standard for the digital transformation of the entire mining industry of Uzbekistan.

Information service