-

Call-center

+998 78 141 90 99 -

Helpline

+998 71 619 23 33

Zinc Plant: A Step toward a Green Future

At the Almalyk Mining and Metallurgical Complex, environmental protection and ecological safety remain priorities. Today, a comprehensive modernization of production is underway, which not only increases production volumes but also minimizes environmental impact. A prime example of such transformations is the zinc smelter.

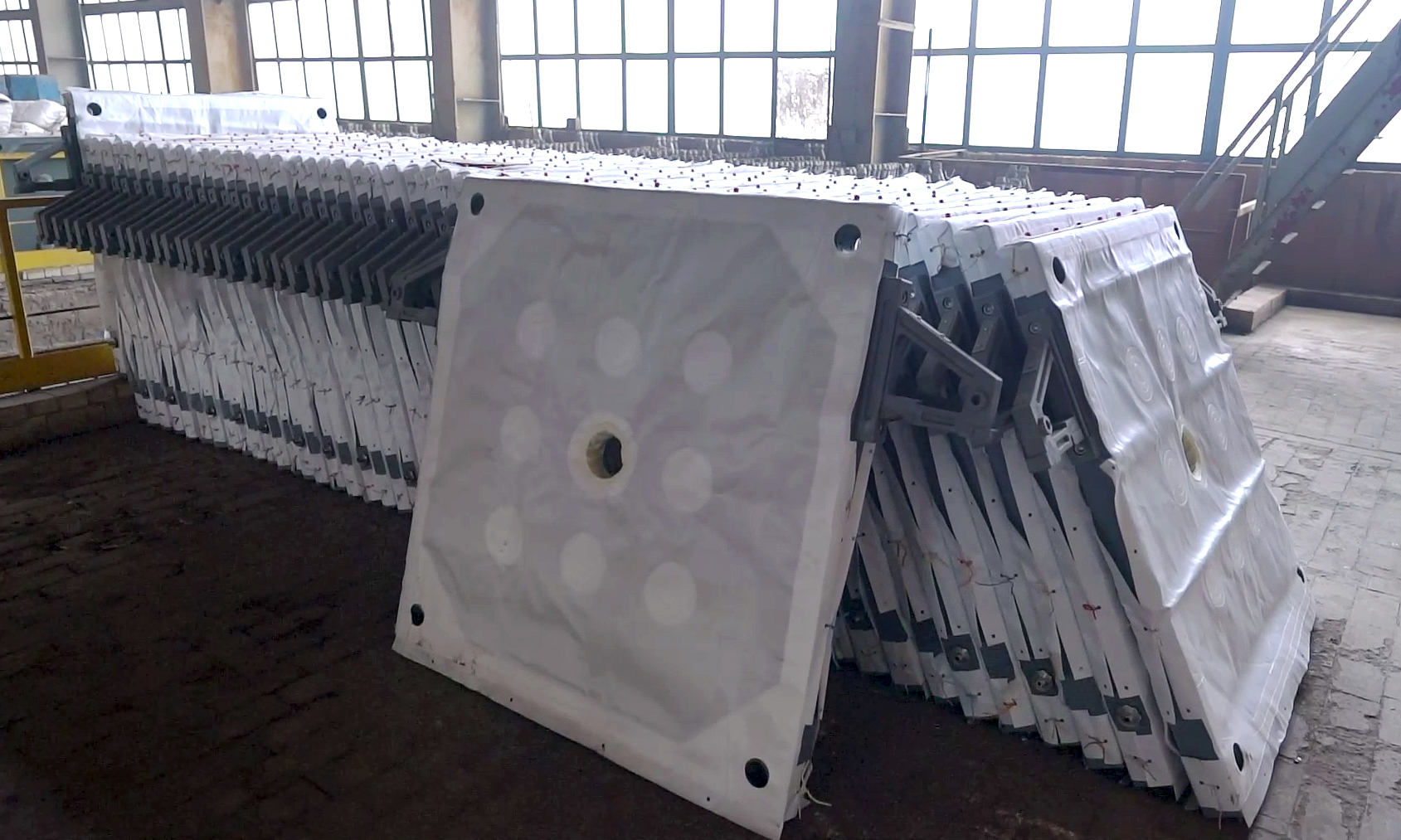

Outdated equipment is being completely replaced at the Waelz shop. Four new press filters have already been commissioned, and two more are in the final stages of installation. These modern units are energy-efficient, highly productive, and fully automated.

In 2025, the new equipment consistently supplied the leaching plant with high-quality zinc filtrate, enabling it to exceed projected zinc and dried zinc pulp production targets.

The introduction of press filters completely eliminated dust emissions, and the discontinuation of natural gas has reduced sulfur dioxide (SO₂) emissions. This not only improves air quality but also reduces zinc losses, previously carried away by dust.

New technologies enable advanced processing of raw materials, reducing product moisture to 16-20%, and maximizing the extraction of useful components. The complete elimination of harmful gas emissions and dust waste has a positive impact on the environmental health of the surrounding area.

Furthermore, replacing of old equipment with new, automated equipment reduces repair and maintenance costs, resulting in savings of over 570 million UZS per year.

The construction of the new Sulfuric Acid Plant No. 6, with an annual capacity of 200,000 tons, is particularly noteworthy. Its launch will completely eliminate pollutant emissions into the atmosphere.

This project is an important part of the AMMC strategic development plan for 2026. It not only takes production to a new level but also takes a significant step toward preserving the environment for future generations.

Information Service