ANGREN TUBE PLANT

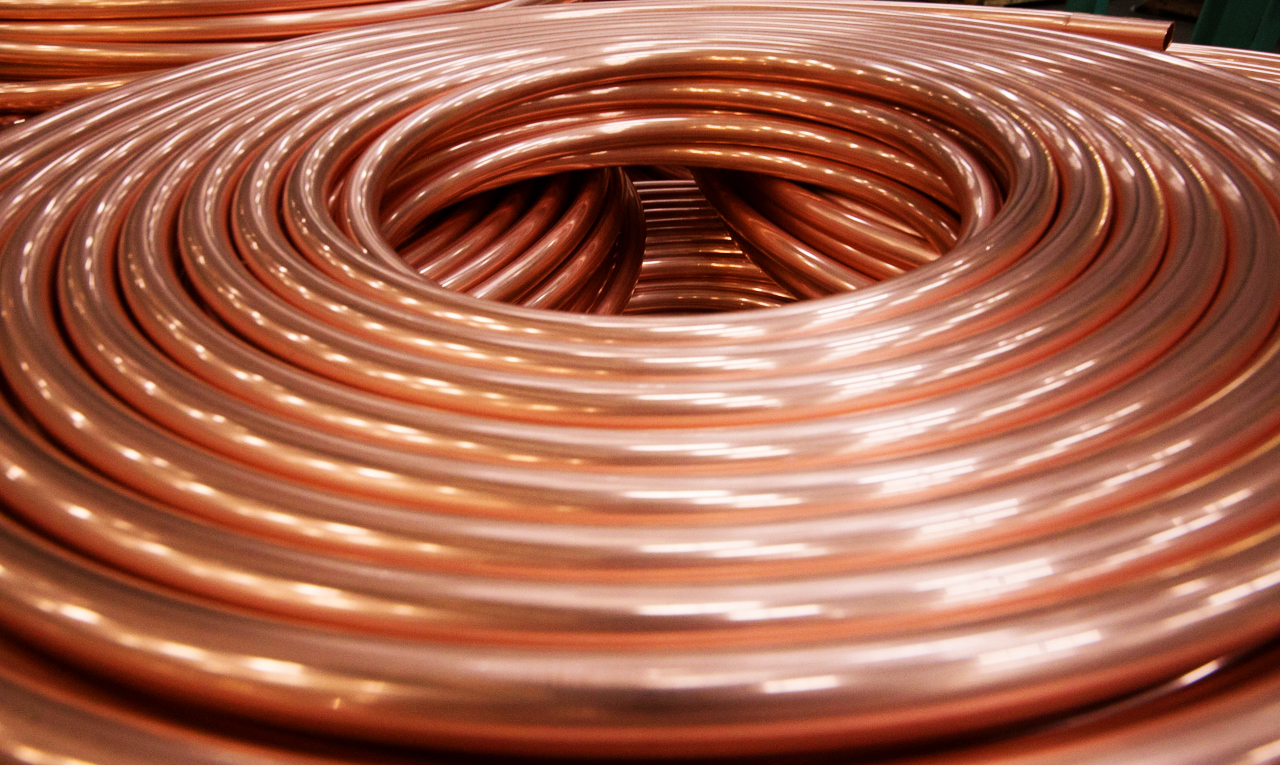

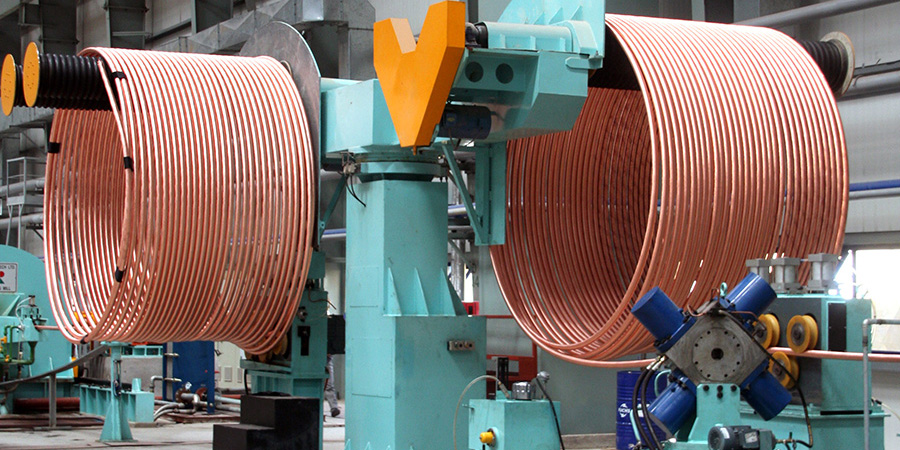

The ‘Angren tube plant’ under JSC ‘Almalyk Mining-Metallurgical Complex (AMMC, Complex) to produce multi-diameter copper tubes (pipes) was erected in the Tashkent region’s special industrial zone (SIZ) of ‘Angren’.

The enterprise’s design capacity is 8,000 t\y. The major raw material is copper cathodes, containing 99.99% of the main metal (GOST 546) is provided by JSC ‘Almalyk MMC’, a largest mining and processing enterprise in the Central-Asian region.

The products made is meant to be exported (90%), as well as for the domestic market (10%).

The purpose:

- arrangement of manufacturing domestic copper tubes;

- widening of the output copper products range;

- providing new jobs;

- ensuring high added value of copper products;

- increase of export potential.

Application

Copper tubes (pipes) are widely used in everyday life, manufacturing, civil work, when laying water supply pipelines, heat supply pipelines, installing climatic equipment, including the following spheres:

- cold and hot water supply;

- hot-water heating and floor water heating systems;

- in compressed air and gas pipelines (gas supply);

- in hydraulic systems for oil supply;

- in systems of connecting of process equipment;

- in fuel supply systems of multi-purpose engines.

In addition, copper and copper alloy pipelines are widely used in shipbuilding and power engineering sectors to convey liquids and steams.

The copper, due to its perfect heat-conducting properties, is the most suitable material to be used in heat engineering, refrigerating engineering and conditioning.

Liquid fuel supply lines is another niche where copper pipes and tubes work successfully. Such fuel supply lines are used also in everyday life, for instance, where gas cannot be used as a fuel. The major fuel in such installations is liquid black oil. The latter being a combustible material, it is important that tightness of the fuel supply line be ensured, and here modern copper pipelines do solve the problem successfully.

Copper pipes advantages:

- Long lifetime (service period of copper water and gas supply pipes is 40 to 80 years).

- High corrosion resistance properties (being non-corrodible, they have long lifetime and lower pipeline maintenance costs).

- Negligible heat expansion.

- Well withstand high and low temperatures. The lowest allowable temperature is minus 100° C. The copper pipes highest allowable operation temperature reaches +250° C level. Though, melting temperature of the copper connections, used in pipeline systems, is over 1,000° C, and this suggests the heat resistance value which is in line with that of refractory pipes.

- Durability (high safety factor of mechanical strength in terms of hydraulic damages).

- Ability to resist high pressures (indifferent to any possible pressure values in water supply systems). The

destruction pressure of a copper pipe is more than 200 atmospheres, so enormous safety factor is ensured.

- Simplicity and easiness of assembly due to high flexibility and elasticity (plasticity) of copper. The material consumption when assembly operations can be calculated to a centimeter (minimal waste).

- High resistance to defrosting (in case of discontinuance or missing of heat- and\or power-supply).

- Resistance to vibrations (indifference to vibrations, in winter time included).

- Gas tightness (impermeable not only for liquids but also for gases, for example, oxygen, this being very critical for heating systems and water supply systems).

- Non-ageing of the material.

- Ecological compatibility (no emission of harmful and toxic compounds) and healthiness.

- Stable towards slurry formation in panel heating systems thanks to 100% diffusion impermeability.

- Healthful, and with high bactericidal and bacteriostatiс properties (that is prevents the bacteria growth on internal side of a pipe).

- Esthetic appearance.

- Extremely small value of the roughness of internal surface and of the local hydraulic resistance loss in connections, which can be just ignored (the roughness in copper pipes is a hundred times less than that in the rest pipes, and 4 to 5 times less than in polymer pipes).

- No fear of ultraviolet effect.

- Copper pipes can be completely reprocessed after their use.

Quality control

Control and tests are performed just at the making site with movable instruments or by equipment-integrated measurement instrumentation, or in the laboratory.

To ensure output quality, the plant analytical laboratory is fit with the equipment of leading companies ‘Zwik\Roell’, ‘Spectro’, ‘ELTRA’ (Germany), providing the carrying out of chemical and physical-mechanical analysis, required to obtain consequently the quality standard as per ISO\MEC 17025.

The analytical Lab of the plant is certified by the Republic of Uzbekistan’s Uz-Standard Agency.