-

Call-center

+998 78 141 90 99 -

Helpline

+998 71 619 23 33

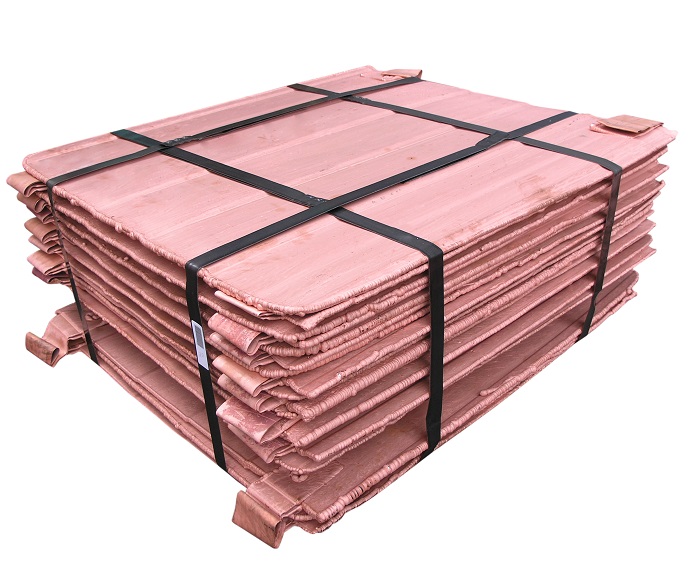

Copper cathodes

Standard:GOST 546-2001

Production cycle:

- copper-molybdenum ore production;

- flotation treatment with obtaining copper concentrate and molybdenum middling product;

- copper matte smelting;

- converting the copper matte with obtaining blister copper;

- blister copper fire refining with copper casting into anodes;

- copper anode electrolysis with production of copper cathodes and slime;

Application range:

Cable and conductor products, copper based alloys production, electrical engineering, copper pipes, motor industry, roofing, etc.

Form and packing:

Cathodes 820 mm x 850 mm x 10 mm, packed as bundles tied up with steel tape, the mass up to 1.5 tons.

brand M00к, Cu – 99.99%

brand M0к, Cu – no less than 99.97%

brand M1к, Cu – no less than 99.95%

The copper cathodes are manufactured as per the GOST 546 requirements ‘Copper cathodes. Specifications’, the chemical composition must conform to the

M00к, M0к, M1к brands copper.

|

Brands |

No less than |

Group Impurities, no more than: |

||||||||||||

|

1 |

2 |

3 |

4 |

5 |

|

|||||||||

|

Cu |

Bi |

Se |

Te |

Sb |

As |

P |

Pb |

S |

Sn |

Ni |

Fe |

Zn |

O |

|

|

М00к |

99,99 |

0,0002 |

0,0002 |

0,0002 |

0,0004 |

0,0005 |

- |

0,0005 |

0,0015 |

- |

- |

0,001 |

- |

0,01 |

|

М0к |

99,97 |

0,0005 |

- |

- |

0,001 |

0,001 |

0,001 |

0,001 |

0,002 |

0,001 |

0,001 |

0,001 |

0,001 |

0,015 |

|

М1к |

99,95 |

0,001 |

- |

- |

0,002 |

0,002 |

0,002 |

0,003 |

0,004 |

0,002 |

0,002 |

0,003 |

0,003 |

0,02 |