-

Call-center

+998 78 141 90 99 -

Helpline

+998 71 619 23 33

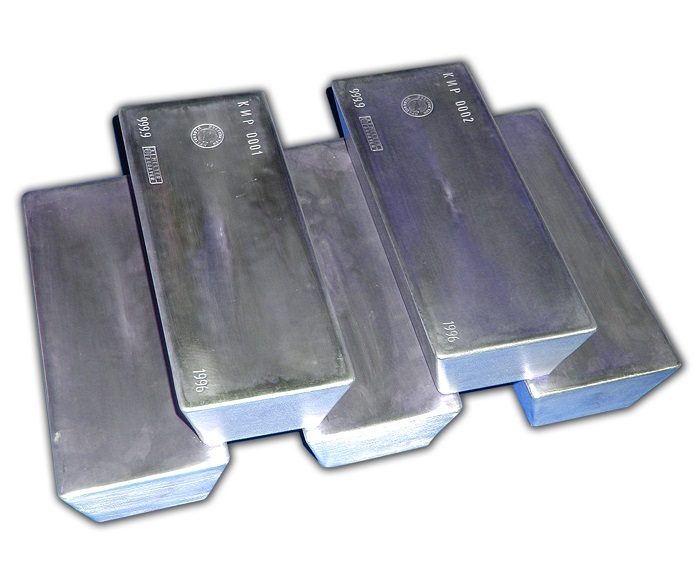

Zinc

Standard:GOST 3640-94

Production cycle:

- roasting the sulfide zinc concentrates in fluid-bed furnaces;

- leaching the zinc cinders and oxides with obtaining the zinc solutions and zinc cake;

- rotary-kiln operation for zinc cakes with producing the zinc oxides;

- clarification of zinc solutions;

- electrolysis of neutral clarified zinc solutions;

- re-melting the cathode zinc to obtain ingots.

Application range:

Galvanic coating, medicine, production of zinc-bearing alloy, production of paint and varnish items, machine building, construction, etc.

Form and packing:

Ingots having a mass of about 25 kg, packed as piles with a mass of not more than 1000 kg and not higher than 500 mm, tied up with a steel tape.

The metal zinc is made as per the GOST 3640 requirements, Ц0А and Ц0 brands.

brand Ц0А, Zn – 99.98%

brand Ц0, Zn – 99.975%

|

Brands |

No less than |

Chemical composition, Impurity percentage, no more than |

||||||

|

|

Zn |

Pb |

Cd |

Fe |

Cu |

Sn |

As |

Всего |

|

Ц0А |

99,98 |

0,01 |

0,003 |

0,003 |

0,001 |

0,001 |

0,0005 |

0,02 |

|

Ц0 |

99,975 |

0,013 |

0,004 |

0,005 |

0,001 |

0,001 |

0,0005 |

0,025 |